31. okt. 2024

Mohamed Ali Memmi

Case Study: Digital Process Planning and Facility Optimization for Ovun New Factory

The Challenge

As Ovun AS prepared to transition from their existing location in Moelv to a new facility at Rudshøgda, they faced the complex challenge of designing a production layout that would maximize operational efficiency and adapt to future growth. They required a solution that enabled flexible, data-driven planning to refine the layout and machinery placement virtually, ensuring the new site would be optimized before physical construction began.

The Solution

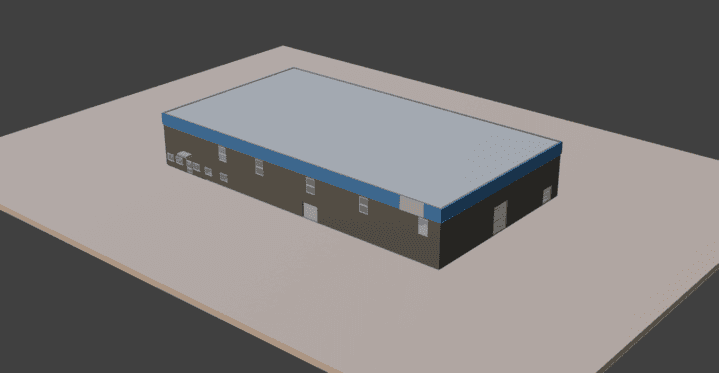

To bring Ovun AS’s new factory vision to life, Moicon collaborated with them to create a detailed 3D digital twin of the planned facility. As an Autodesk APS Tech Partner, Moicon utilized Autodesk Platform Services (APS), specifically the Data Management API and Model Derivative API, to develop an integrated, data-driven digital model. This allowed Ovun to visualize the factory layout within its surroundings at Rudshøgda and connect essential facility data and IoT sensor information for enhanced operational insights.

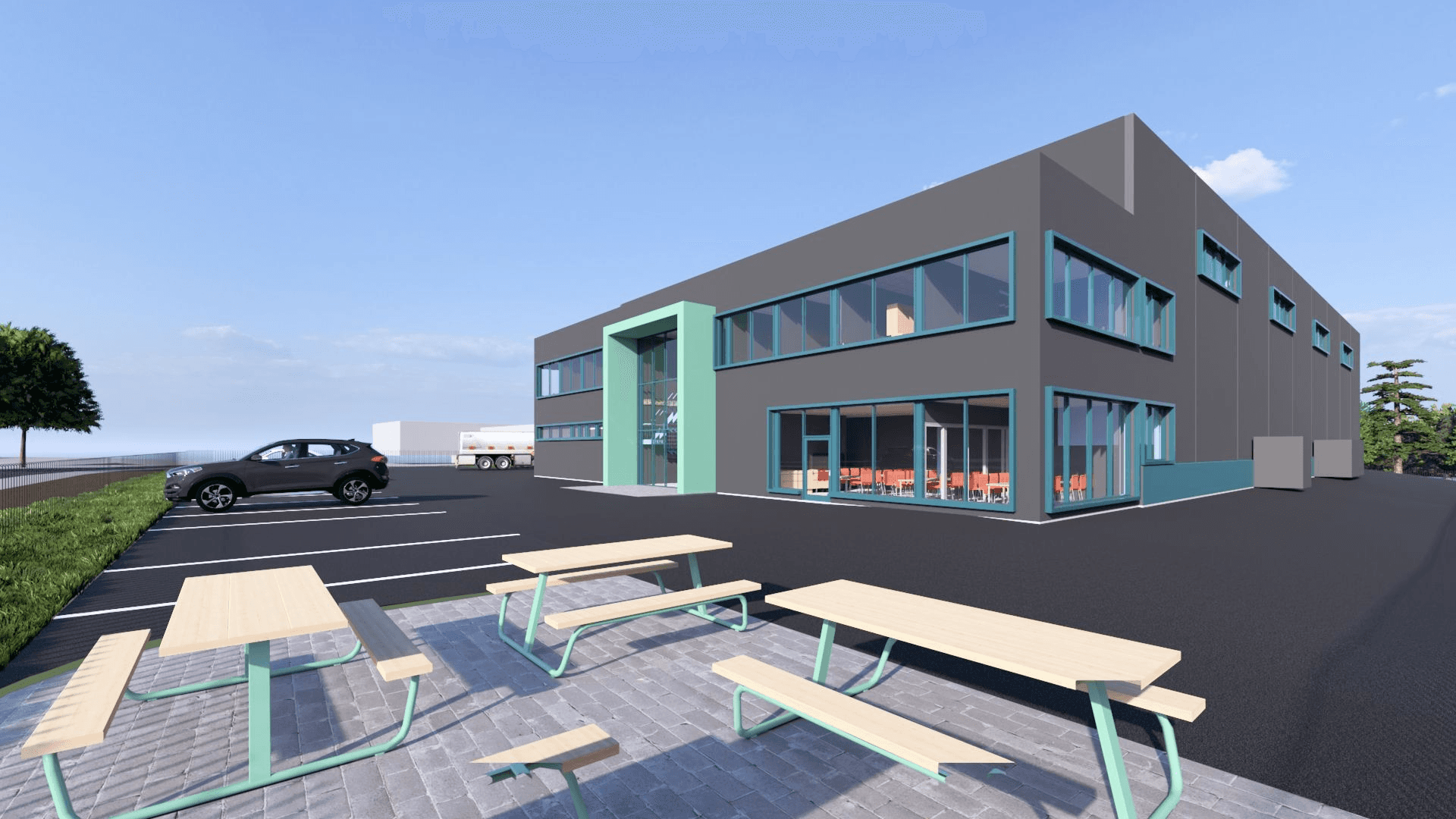

Moicon also leveraged Autodesk Forma to enrich the digital twin with precise 3D modeling and real-time environmental data integration. This comprehensive approach provided Ovun with an adaptable planning tool that enabled the testing and refining of different layout configurations and machinery placements before construction commenced. By adopting this digital-first methodology, Ovun could make data-driven decisions confidently, reducing potential delays and cost overruns while ensuring an optimized factory design ready for future scalability and operational excellence.

This collaborative use of APS technology and Autodesk Forma exemplifies how Moicon’s solutions deliver significant value, enhancing efficiency and adaptability for complex projects.

Discover the capabilities of Autodesk Forma and learn more about Autodesk Platform Services.

Initial 3D Model

Final Optimized Version

Key Solution Highlights:

Virtual Layout Testing and Refinement: Using the digital twin, Ovun tested and optimized different layout configurations and machinery placements, ensuring the factory setup would meet their operational goals.

Real-World Environment Integration: Autodesk’s capabilities allowed Ovun to incorporate the surrounding area of the new building, providing a realistic view of the facility’s placement within its environment.

Strategic Collaboration: Ovun collaborated with Tema Eiendom AS and selected Veidekke Norge as the general contractor, leveraging Veidekke’s expertise from prior projects to enhance project continuity and execution.

Moicon’s Delivery

Moicon’s Digital Twin enabled Ovun AS to simulate “what-if” scenarios across multiple stages of planning, helping them make data-informed decisions on process flow, layout configurations, and resource allocation. This virtual approach provided flexibility and foresight, allowing Ovun to adjust layouts proactively. By implementing these changes in the digital twin, Ovun minimized the risk of costly modifications post-construction and optimized production efficiency from the outset.

Results

Leveraging Moicon’s Digital Twin and Autodesk’s integrated technology, Ovun AS achieved:

Streamlined Planning and Decision-Making: The ability to validate configurations virtually allowed for faster, data-driven planning, reducing planning time and aligning with project goals.

Multi-Stage Optimization of Layout and Machinery Placement: Ovun refined and adjusted the factory setup at multiple stages, allowing them to finalize the layout before construction commenced.

Cost Savings on Physical Adjustments: Virtual simulations reduced the need for post-construction changes, preserving resources and budget.

Enhanced Production Flow through a fully optimized, data-informed layout tailored to Ovun’s operational needs.

Scalable, Future-Ready Facility: The digital twin positions Ovun for seamless adjustments in response to future demands, ensuring the facility can evolve alongside production needs.

Customer Testimonial

With Moicon’s Digital Twin, we established a 3D model of our factory, allowing us to adjust and optimize machine placement based on workflow principles, forming the foundation for future process simulations

Moicon Chatbot

Moicon Chatbot